Are there any problems akin to the cases below in your factories?

- I would like to visualise the process of production in the line. To gather sufficient information efficiently, I need a KANBAN system displaying the state of production in different lines.

- I want to introduce AGV or component storage equipments such as FUJI Tower to further automate my factory but I am not sure of how to connect them to MMS, MES.

- I would like production line operators to work effectively across their responsible lines. This would be useful in a situation where operators of one line is busy changing operation type while operators of another line is operating normally at ease.

- Line operators are unable to react swiftly to certain errors such as "component running out" as they are unaware of the line status in real time. I would like to have a system that clarifies such issues to the operators so they could resolve it quickly.

- I have prepared components for a specific production line, but it ran out earlier than planned as some components were shared across production lines. Occasionally some lines would stop momentarily because of lack of components, but it is also a great hustle to take into account how much sharing is going to occur between lines.

- I am not sure if the components storage management in my factory is accurate and real-time. It will cause a huge loss if there are not enough components and our production line gets halted.

- There are too many type of components being stored and it is becoming harder to comprehend where each components are located. It is taking time to locate where the desired item is, and I would like to reduce this time cost.

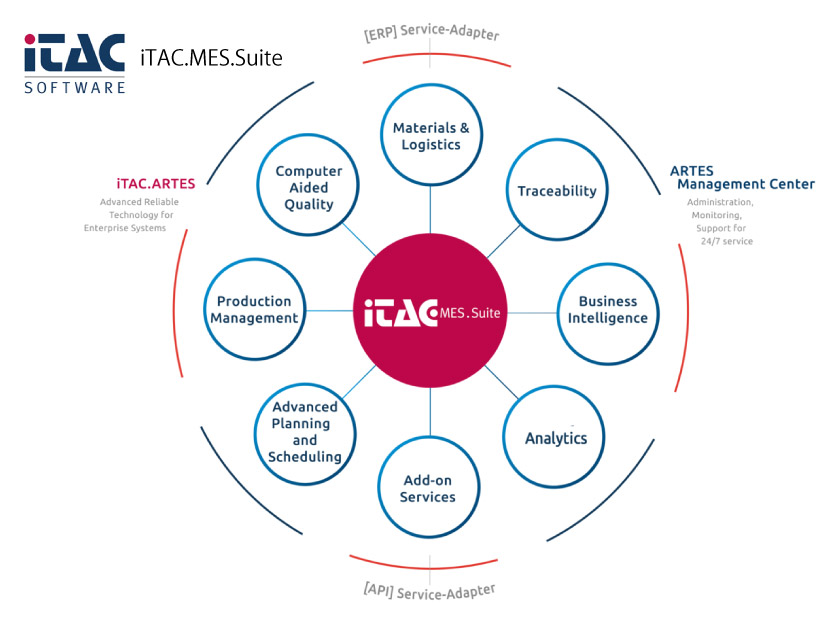

First Technology's software development team has been successfully resolving above types of issue for our customerss. For customers that would like to introduce MES (Manufacturing Execution System), we recommend products from iTAC in Germany, as they are relied on by firms of various industries (e.g. car assembly, medical equipments).